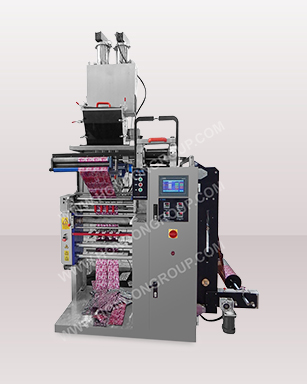

This machine is suitable for medical, health care product, food industrial powdery materials, such as herbal powder, protein powder, coffee etc.

This machine adopt full servo motor control system, with accurate action, fast speed, no need maintenance.

This machine adopt the intermittent sealing system, this special sealing system make the pattern more clearly, with good airtight, and avoid the bag leakage and wrinkle.

We are the exclusive factory who adopt the movable feeding system which makes the measuring adjustment more simple. Servo motor control straight auger device can make sure there is no feed leakage when machine running, the sealing margin is clean and with good airtight. When cleaning the auger, he no need to remove the bag forma, it’s more convenient and simple.

External cutter adjusting device, you can adjust the cutter position with no machine stop, more convenient and safety.

If adopt the double cutter system can achieve N bags a cut, which reduce the cartoning labor intensity and ensure the cartoning numbers accuracy.

Packaging Materials

Polyester/polyethylene (low temperature), polyester/polyester aluminized/polyethylene (low temperature), polyester/pure aluminum/polyethylene (low temperature).

Packaging requirements

Thickness ≤ 10 wire, coil inner diameter 75mm, coil outer diameter ≤ 300mm.

Technical parameters

| Model | DXDF-40VII(connected Bags) |

| Bag Size | L 50-120mm/W 40-90mm |

| Max Capacity | 80-100 Bags/Min(Take flour as an example) |

| Max Filling Range | 40ml |

| Power | 220V,50HZ,3.5KW |

| Weight | 450kg |

| Dimension(L×W×H) | 1100x1000x2000 |