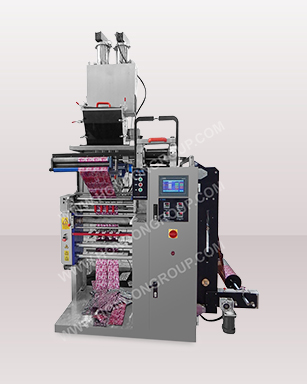

This machine is suitable for mass production of medical, health care product and food liquid product, such as CPG, Ginseng liquid, syrup and honey etc.

Different shaped sealing type improve the product quality, easy to tear and tight sealing without any clip material.

The whole machine adopt servo motor+PLC touch screen control system, which is much easier to operate; Air driver sealing system make the machine run more steady.

This machine adopt special bag making system which can make the bag neat and much beauty.

Independent research and development designed special volume method is specialized for stick material. It can keep the sealing margin clean, no clip material.

Servo motor control feeding system, you can adjust the feeding through the touch screen. It’s very easy to operate. With perfect structure, you can increase the production rate greatly and reduce the labor cost.

Packaging Materials

Polyester/polyethylene (low temperature), polyester/polyester aluminized/polyethylene (low temperature), polyester/pure aluminum/polyethylene (low temperature).

Packaging requirements

Thickness ≤ 10 wire, coil inner diameter 75mm, coil outer diameter ≤ 300mm

Technical parameters

| Model | DXDY-900T |

| Max Film Width | 900mm |

| Capacity | 30-60 Bags/Min/Line |

| Max Filling Range | 40ml |

| Power | 380V,50HZ,5KW |

| Air Consumption | 0.5L/Min |

| Weight | 1500kg |

| Dimension(L×W×H) | 1370×1700×2500 |